|

|

|

PMC

Engineering

Solutions provides engineering and consulting services

to all industries that have flow accelerated corrosion

(FAC)/erosion/degradation concerns in

pressure boundaries, with a particular focus on Code compliance issues

in vessels, heat exchangers and piping. Design services

include

application of the patented “PMC Restoration

Method”, Flow Restriction Devices (Orifice Plates), ASME

pressure vessel design, Fitness for Service (FFS) evaluations, Finite

Element Analysis (FEA), mechanical engineering, and structural

analysis.

|

|

Specific

engineering services include:

Flow Restriction Devices [Orifice Plates - Design / Build]

|

| PMC Engineering is capable of designing and

fabricating orifice plates to aid in your volumetric flow rate

measurements. We can design and build orifice plates for any

industry, code and application. |

Fitness

for Service Code Evaluations

|

| PMC

Engineering services have been used extensively to determine the

capability of components with degraded pressure boundary, including

localized metal loss and pits, in shells and nozzles, to remain in

service while satisfying ASME Code criteria. Our Fitness for

Service

evaluations determine how long a component can remain in service before

repair is required. Evaluations are performed using in-house

developed

metal loss prediction and Code compliance software, along with detailed

finite element methods. Results of our evaluations can allow

for

continued operation and provide sufficient time to adequately plan for

repairs on a non-emergency basis. |

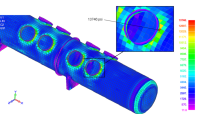

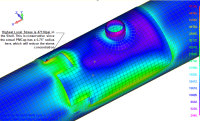

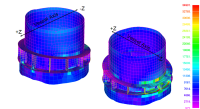

Finite

Element Analysis

|

| PMC

Engineering

utilizes finite element methods to perform component and structure

analyses that provide accurate and economical hardware designs and

evaluations. Use of finite element methods can reduce the

inherent conservatism and provide more accurate stress and factor of

safety results than those obtained using conventional hand calculations

or design by rule methods. Work is performed using ANSYS,

NASTRAN, or Algor finite element analysis software. |

|

|

|

| Fitness

for Service Finite Element Analysis |

PMCap

Shell Finite Element Analysis |

PMNozzleCap

Finite Element Analysis |

Section

VIII/III Fabrication

|

| PMC

Engineering

provides

ASME Code pressure vessel engineering, design services, fabrication

management

and inspection services for ASME Section VIII components to the

commercial

industry and ASME Section III components to the nuclear

industry.

Code stamped components can be procured from

PMC Engineering. PMC Engineering also

provides design and supply of Code component

“U-PART” and

“NPT” stamped

restoration hardware including the patented PMCap (US Patent 6,960,297)

hardware for restoration of degraded pressure boundary areas by

encapsulation. |

Temporary

Repairs Designed to Code

|

| PMC

Engineering can

design, construct, and supply cost effective temporary repair hardware

that

satisfy Code construction requirements and requisite safety factors for

the

duration of the temporary repair use.

Where plant down time is of paramount importance, a temporary (but Code

compliant) repair can sometimes provide the best solution.

PMC

Engineering has extensive experience

working with our clients to determine the most cost effective approach

to

component repair considering both equipment end of life date and plant

demands

on equipment return to service needs. |

Pressure

Vessel Design/Re-Rate

|

| PMC

Engineering

specializes in the design of high and low temperature pressure vessels

to ASME

Section III and Section VIII Division 1 and 2 criteria. Our

designs have

been used in radioactive waste gas processing at temperatures above

1200°F and

cryogenic industrial gas production at temperatures below

-320°F. We have

extensive experience in re-rating vessels for operation under different

pressure/temperature and loading conditions than for which they were

originally

designed and certified. |

Piping

|

| PMC

Engineering

provides design of high and low

temperature piping systems

that optimize supports and equipment loading that satisfies ASME

Section III,

ASME B31.1 and B31.3 design criteria. |

Welding Services

|

| PMC

Engineering has agreements in place with highly qualified

welding and field installation, repair and restoration

contractors.

We manage our contractor services to assure

compliance with ASME Codes and National Board inspection Code (NBIC)

requirements. |

Field

Management Services

|

| PMC

Engineering

provides management services to support our clients during field

installations,

repairs and restorations that utilize our recommended component

remediation

work or supplied hardware. |

|

|